FIC FOOD PROCESSING TANKS

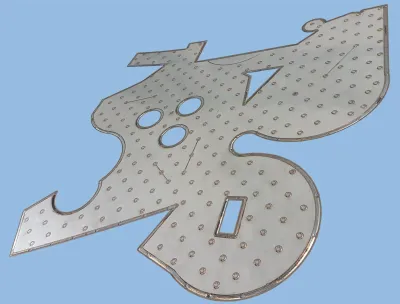

The TECNOTANK processing tanks produced by FIC S.p.A are designed for the heat treatment of numerous fluids. All tanks come with a PILLOW PLATE heat exchanger sleeve and/or base, and a stirrer system designed in size around the characteristics of the fluid concerned.

TECNOTANKS can be supplied in AISI 304 or AISI 316L stainless steel. Special features (such as specific couplings, hatches and outlets) are created face to face with the client. The capacities range from 150 litres to 15-20,000 litres. The design is normally cylindrical and vertical. FIC S.p.A can also produce tanks which can be used under pressure with the relevant PED 2014/68/EU certification.

Some examples of TECNOTANKS are: tanks for cream with anchor stirrers, yoghurt tanks, chocolate temperature control tanks, brining tanks, honey tanks and wax tanks.

Melting tanks are a sub-range of TECNOTANKS: this refers to particular tanks which have a heating grill (with water) in the upper part of the internal vessel, on which the product to be melted is positioned in solid form. Thanks to the heat exchange, the product changes to a liquid and is gathered on the bottom of the tank, where a stirrer and the bottom of the PILLOW PLATE heat exchanger hold it at a constant temperature in liquid form. Typical uses are for butter or chocolate and it is often used in the confectionery and ice-cream industries.